Surface analysis platform for Aerospace OEM Manufacturers

Increase productivity and reduce costs with instant 3D surface analysis

7 of the top 10 aerospace OEM manufacturers are using GelSight today to get better accuracy, repeatability, and resolution than existing surface inspection systems, in real time and for any kind of material…. Why?

√ Precise, repeatable, non-destructive testing for manufacturing/MRO operations of engines, landing gears, fuselages, and other critical components

√ Compatibility with metallic and composite materials and other highly reflective or transparent surfaces common in the industry

AEROSPACE APPLICATIONS

OEM and Manufacturing: Immediate surface analysis for quality control of manufacturing/assembling processes

Maintenance Repair Overhaul: Accurate and detailed information to reduce rework and/or increase yield leading to reduction of DMC and Turn Around Time

Scratch and dent measurement

Early corrosion characterization

Surface defect detection

Fastener flushness measurement

Pit detection

Hole measurement

XYZ dimensional measurements

Weld inspection

...and more

WHY GELSIGHT?

"We had the opportunity to evaluate Series 2 and have been impressed by its performance. Its compact and lightweight design will definitely increase the number of use cases and will accelerate our return on investment."

-Yann Siehen, Safran Helicopter Engines

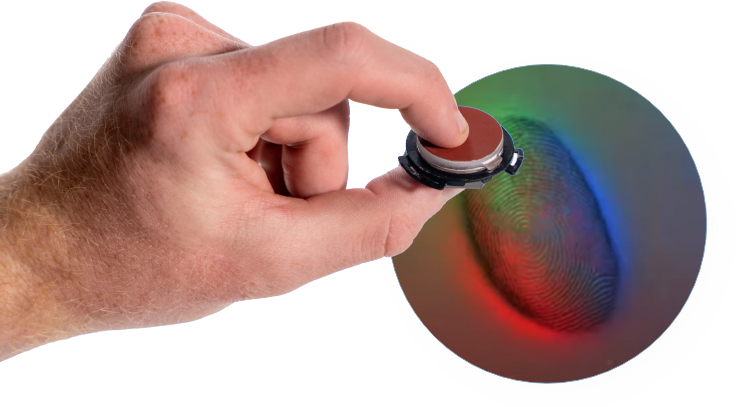

Proprietary Elastomeric Platform

At the heart of GelSight’s digital touch technology is our proprietary elastomeric platform. It creates a soft, high-resolution, tactile sensor that conforms like human skin to the shape of an object on contact, precisely capturing the topography of the surface.

Digital Touch

Data captured by our elastomeric tactile sensing platform is instantly analyzed in our proprietary operating system to provide detailed, 3D information on surface features, regardless of lighting or material reflectivity. The result is accurate surface characterization thanks to GelSight’s Digital Touch technology.